Shielded or Unshielded? Comparing ÖLFLEX® 190 & 190 CY Cables

-

LAPP Tannehill

LAPP Tannehill - Product News

- Dec 31, 2024

- 608views

Shielded or Unshielded? Comparing LAPP ÖLFLEX® 190 & 190 CY

Discover the differences between LAPP ÖLFLEX® 190 & 190 CY multiconductor cables, their applications, and their benefits for industrial power and control needs.

LAPP's ÖLFLEX® range is synonymous with innovation, reliability, and efficiency in the world of industrial cabling. Among its vast portfolio, ÖLFLEX® 190 and ÖLFLEX® 190 CY cables stand out as versatile solutions for power and control applications.

These multiconductor cables cater to various industrial needs, offering high performance in challenging environments. But how do they differ, and which one suits your needs better? This blog post dives deep into the specifications, applications, and advantages of both cables, with a detailed comparison to help you make an informed decision.

Overview of ÖLFLEX® 190

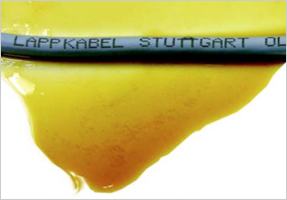

ÖLFLEX® 190 is a multi-conductor cable designed for industrial power and control applications. It is known for its robust design and resistance to environmental factors, making it ideal for demanding industrial environments. Key features include:

Construction: Made with finely stranded bare copper conductors for flexibility

Insulation: Specially formulated PVC insulation ensures durability and reliability

Outer Jacket: A rugged PVC outer jacket provides resistance to oil, chemicals, & mechanical stress

Temperature Range: Suitable for operations in temperatures ranging from -13°F (-25°C) to 194°F (90°C)

Certifications: Meets UL & CSA standards, ensuring compliance with North American safety regulations

ÖLFLEX® 190 Applications

The ÖLFLEX® 190 is ideal for a wide range of industrial applications, including:

Power Circuits: Efficiently handles power distribution in industrial equipment

Control Systems: Suitable for control circuits in machinery & production lines

General Purpose Wiring: Versatile for various wiring needs in industrial setups

Overview of ÖLFLEX® 190 CY

ÖLFLEX® 190 CY shares many features with ÖLFLEX® 190 but includes an additional layer of shielding. This makes it particularly suitable for environments where electromagnetic interference (EMI) is a concern. Key features include:

Shielding: An overall tinned copper braid provides excellent EMI protection

Construction: Similar to ÖLFLEX® 190, with finely stranded bare copper conductors

Outer Jacket: A durable PVC outer jacket, resistant to oil, chemicals, & mechanical stress

Temperature Range: Operates in the same temperature range as ÖLFLEX® 190

Certifications: Meets UL & CSA standards, ensuring compliance with North American safety regulations

ÖLFLEX® 190 CY Applications

With its EMI shielding, ÖLFLEX® 190 CY is designed for more specialized applications, such as:

Signal Transmission: Protects sensitive signals from external interference

Automation Systems: Ensures reliable communication in automated processes

Data Processing Equipment: Ideal for wiring in data and communication systems

Advantages of Shielding in ÖLFLEX® 190 CY

The additional shielding in the ÖLFLEX® 190 CY offers several advantages:

Reduced Electromagnetic Interference: Ensures clean & accurate signal transmission

Enhanced Reliability: Minimizes disruptions in control and data systems

Increased Versatility: Suitable for environments with high levels of electrical noise

Check out Shielding Types Comparison Chart to learn whether you may need shielding with your application.

Application Use Cases for ÖLFLEX® 190 & 190 CY Cables

Application Use: Automotive Manufacturing

In an automotive manufacturing plant, high-speed assembly lines require reliable power and control cabling to operate robotic arms and conveyor systems. The plant's engineers use ÖLFLEX® 190 cables for their flexibility and oil-resistant properties. These cables effectively handle the demanding environment, ensuring uninterrupted power delivery to robotic systems. Their durability minimizes downtime, leading to production efficiency.

Meanwhile, ÖLFLEX® 190 CY cables are used in areas prone to electromagnetic interference, such as quality inspection stations with high-precision sensors. The shielding prevents signal disruptions, maintains accurate measurements and ensures product quality.

Application Use: Food and Beverage Industry

In a food processing facility, hygiene and chemical resistance of cables are crucial. ÖLFLEX® 190 cables are installed to power conveyor systems and automated packaging machines. Their resistance to oils and cleaning agents ensures compliance with sanitation standards while providing reliable operation.

For the facility's data processing systems, ÖLFLEX® 190 CY cables are chosen to mitigate EMI from nearby equipment. This ensures seamless communication between sensors and control systems, reducing errors in portioning and packaging processes. The result is waste reduction and improved operational consistency.

Application Use: Renewable Energy Sector

A solar power plant requires robust cabling to connect photovoltaic panels to inverters and control units. ÖLFLEX® 190 cables are deployed for their UV-resistant outer jacket and ability to handle fluctuating temperatures. This provides a cost-effective solution for power transmission, ensuring reliable energy delivery.

In the plant's control room, ÖLFLEX® 190 CY cables connect monitoring equipment and prevent EMI from interfering with data accuracy. This enables precise tracking of energy production and system performance, enhancing the plant's efficiency and reliability.

Comparison Table: ÖLFLEX® 190 vs. ÖLFLEX® 190 CY

| ÖLFLEX® 190 | ÖLFLEX® 190 CY | |

|---|---|---|

| Conductor Material | Bare copper | Bare copper |

| Shielding | None | Tinned copper braid |

| Outer Jacket Material | PVC | PVC |

| Temperature Range | -13°F (-25°C) to 194°F (90°C) | -13°F (-25°C) to 194°F (90°C) |

| Oil Resistance | High | High |

| Chemical Resistance | High | High |

| Certifications | UL, CSA | UL, CSA |

| Applications | Power and control systems | EMI-sensitive applications |

| Cost | Lower | Slightly higher due to shielding |

Choosing the Right Cable

When deciding between ÖLFLEX® 190 and 190 CY, consider the following factors:

Environment: For environments with significant electrical noise, ÖLFLEX® 190 CY is the better choice

Budget: If cost is a primary concern and EMI is not an issue, ÖLFLEX® 190 offers a cost-effective solution

Compliance: Both cables meet stringent safety standards, so both ensures compliance

Application Needs: Assess the specific requirements of your application, such as signal integrity or power transmission

ÖLFLEX® 190 and ÖLFLEX® 190 CY are robust multiconductor cable solutions that cater to diverse industrial needs. While ÖLFLEX® 190 excels in general power and control applications, ÖLFLEX® 190 CY provides an edge in EMI-sensitive environments. Understanding your application's unique requirements will help you select the cable that best meets your needs. By choosing LAPP’s ÖLFLEX® range, you invest in reliability, efficiency, and performance that stands the test of time.

Shielded or Unshielded? Comparing LAPP ÖLFLEX® 190 & 190 CY

Discover the differences between LAPP ÖLFLEX® 190 & 190 CY multiconductor cables, their applications, and their benefits for industrial power and control needs.

LAPP's ÖLFLEX® range is synonymous with innovation, reliability, and efficiency in the world of industrial cabling. Among its vast portfolio, ÖLFLEX® 190 and ÖLFLEX® 190 CY cables stand out as versatile solutions for power and control applications.

These multiconductor cables cater to various industrial needs, offering high performance in challenging environments. But how do they differ, and which one suits your needs better? This blog post dives deep into the specifications, applications, and advantages of both cables, with a detailed comparison to help you make an informed decision.

Overview of ÖLFLEX® 190

ÖLFLEX® 190 is a multi-conductor cable designed for industrial power and control applications. It is known for its robust design and resistance to environmental factors, making it ideal for demanding industrial environments. Key features include:

Construction: Made with finely stranded bare copper conductors for flexibility

Insulation: Specially formulated PVC insulation ensures durability and reliability

Outer Jacket: A rugged PVC outer jacket provides resistance to oil, chemicals, & mechanical stress

Temperature Range: Suitable for operations in temperatures ranging from -13°F (-25°C) to 194°F (90°C)

Certifications: Meets UL & CSA standards, ensuring compliance with North American safety regulations

ÖLFLEX® 190 Applications

The ÖLFLEX® 190 is ideal for a wide range of industrial applications, including:

Power Circuits: Efficiently handles power distribution in industrial equipment

Control Systems: Suitable for control circuits in machinery & production lines

General Purpose Wiring: Versatile for various wiring needs in industrial setups

Overview of ÖLFLEX® 190 CY

ÖLFLEX® 190 CY shares many features with ÖLFLEX® 190 but includes an additional layer of shielding. This makes it particularly suitable for environments where electromagnetic interference (EMI) is a concern. Key features include:

Shielding: An overall tinned copper braid provides excellent EMI protection

Construction: Similar to ÖLFLEX® 190, with finely stranded bare copper conductors

Outer Jacket: A durable PVC outer jacket, resistant to oil, chemicals, & mechanical stress

Temperature Range: Operates in the same temperature range as ÖLFLEX® 190

Certifications: Meets UL & CSA standards, ensuring compliance with North American safety regulations

ÖLFLEX® 190 CY Applications

With its EMI shielding, ÖLFLEX® 190 CY is designed for more specialized applications, such as:

Signal Transmission: Protects sensitive signals from external interference

Automation Systems: Ensures reliable communication in automated processes

Data Processing Equipment: Ideal for wiring in data and communication systems

Advantages of Shielding in ÖLFLEX® 190 CY

The additional shielding in the ÖLFLEX® 190 CY offers several advantages:

Reduced Electromagnetic Interference: Ensures clean & accurate signal transmission

Enhanced Reliability: Minimizes disruptions in control and data systems

Increased Versatility: Suitable for environments with high levels of electrical noise

Check out Shielding Types Comparison Chart to learn whether you may need shielding with your application.

Application Use Cases for ÖLFLEX® 190 & 190 CY Cables

Application Use: Automotive Manufacturing

In an automotive manufacturing plant, high-speed assembly lines require reliable power and control cabling to operate robotic arms and conveyor systems. The plant's engineers use ÖLFLEX® 190 cables for their flexibility and oil-resistant properties. These cables effectively handle the demanding environment, ensuring uninterrupted power delivery to robotic systems. Their durability minimizes downtime, leading to production efficiency.

Meanwhile, ÖLFLEX® 190 CY cables are used in areas prone to electromagnetic interference, such as quality inspection stations with high-precision sensors. The shielding prevents signal disruptions, maintains accurate measurements and ensures product quality.

Application Use: Food and Beverage Industry

In a food processing facility, hygiene and chemical resistance of cables are crucial. ÖLFLEX® 190 cables are installed to power conveyor systems and automated packaging machines. Their resistance to oils and cleaning agents ensures compliance with sanitation standards while providing reliable operation.

For the facility's data processing systems, ÖLFLEX® 190 CY cables are chosen to mitigate EMI from nearby equipment. This ensures seamless communication between sensors and control systems, reducing errors in portioning and packaging processes. The result is waste reduction and improved operational consistency.

Application Use: Renewable Energy Sector

A solar power plant requires robust cabling to connect photovoltaic panels to inverters and control units. ÖLFLEX® 190 cables are deployed for their UV-resistant outer jacket and ability to handle fluctuating temperatures. This provides a cost-effective solution for power transmission, ensuring reliable energy delivery.

In the plant's control room, ÖLFLEX® 190 CY cables connect monitoring equipment and prevent EMI from interfering with data accuracy. This enables precise tracking of energy production and system performance, enhancing the plant's efficiency and reliability.

Comparison Table: ÖLFLEX® 190 vs. ÖLFLEX® 190 CY

| ÖLFLEX® 190 | ÖLFLEX® 190 CY | |

|---|---|---|

| Conductor Material | Bare copper | Bare copper |

| Shielding | None | Tinned copper braid |

| Outer Jacket Material | PVC | PVC |

| Temperature Range | -13°F (-25°C) to 194°F (90°C) | -13°F (-25°C) to 194°F (90°C) |

| Oil Resistance | High | High |

| Chemical Resistance | High | High |

| Certifications | UL, CSA | UL, CSA |

| Applications | Power and control systems | EMI-sensitive applications |

| Cost | Lower | Slightly higher due to shielding |

Choosing the Right Cable

When deciding between ÖLFLEX® 190 and 190 CY, consider the following factors:

Environment: For environments with significant electrical noise, ÖLFLEX® 190 CY is the better choice

Budget: If cost is a primary concern and EMI is not an issue, ÖLFLEX® 190 offers a cost-effective solution

Compliance: Both cables meet stringent safety standards, so both ensures compliance

Application Needs: Assess the specific requirements of your application, such as signal integrity or power transmission

ÖLFLEX® 190 and ÖLFLEX® 190 CY are robust multiconductor cable solutions that cater to diverse industrial needs. While ÖLFLEX® 190 excels in general power and control applications, ÖLFLEX® 190 CY provides an edge in EMI-sensitive environments. Understanding your application's unique requirements will help you select the cable that best meets your needs. By choosing LAPP’s ÖLFLEX® range, you invest in reliability, efficiency, and performance that stands the test of time.

Related Posts

Need a Quote?

Our quick quote form is an easy way to get you the information you need to keep your project on track.

If you still have questions, chat with us online or call us at 800.633.6339. Our customer service representatives are available to answer questions Monday through Friday, 8am - 5pm CST.

Customer Portal | Online Account Management Tool for Current Customers Log In