Everything You Need to Know About Cord Grips

Heavy-duty cables are found everywhere you turn – from arenas and large facilities to commercial buildings. They play a vital component in bringing our indoor environments to life.

Now imagine what could happen if one of these cables disconnects. Unplanned outages, equipment malfunction, and downtime could lead to potential injury, missed production deadlines, and efficiency interruptions – all negatively impacting the bottom line.

Cord grips are crucial in ensuring uptime and preventing cable disconnects. However, they aren’t always given adequate consideration when planning cable infrastructure. For a small investment, cord grips guard against downtime and equipment failure.

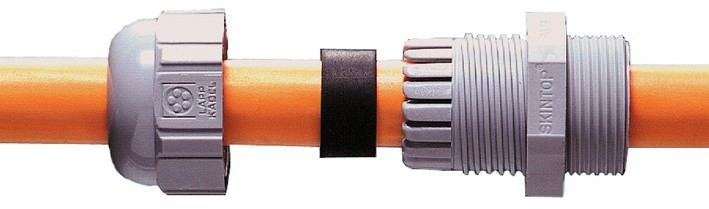

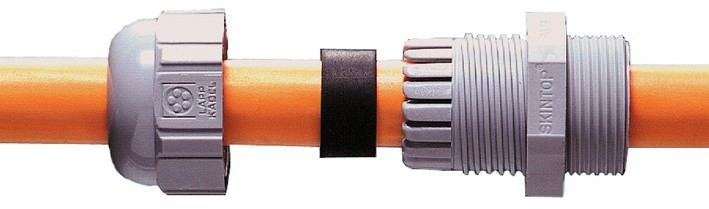

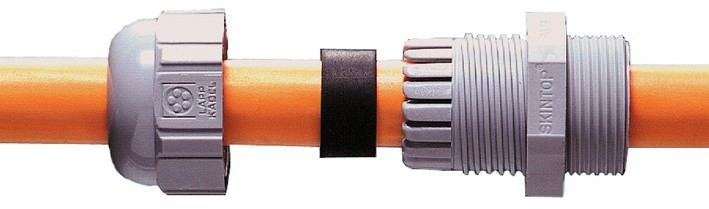

What is a Cord Grip?

Cord grips are devices that attach and secure heavy-duty cables to equipment. They can seal around single or multiple wires or cables – armored or unarmored.

Cord Grips vs. Cable Glands

Cord grips and cable glands are different names for the same thing, with cord grip being more commonly used within the United States. Depending on the region you are located in, they may be known as cable glands, connectors, strain relief, or fittings. Here at LAPP Tannehill, we tend to use 'cord grip' and 'cable gland' interchangeably.

What Are Cord Grips Made Of?

Most cord grips are made up of three components: two “halves” and a grommet.

- The front half of the cable gland secures the gland itself, often called a cap nut or dome cap.

- The middle section (grommet) seals and locks the cable into place so it can’t be pulled or tugged loose.

- The final half holds the entire gland together, often called the thread.

To withstand a variety of environments, cord grips are available in a variety of metals and plastics. The right choice depends on your application. Some of the most common materials include:

Metal

- Aluminum is lighter in weight than stainless steel, offers excellent electrical and thermal conductivity, and resists corrosion and wear

- Brass offers high-temperature ductility, impressive bearing properties, high conductivity, good corrosion resistance, and low magnetic permeability

- Stainless steel provides chemical and corrosion resistance, better tensile strength than aluminum, and durability even in wet conditions

Plastic

- Nylon is durable and lightweight, withstands moisture and corrosion, and is available in different colors for cable color coding (which can support easier maintenance )

- PVC is flexible and easy to clean and is also ideal in food and chemical processing environments because it resists salt water, grease, and weak acids

There are also different choices you can make when it comes to joining a cord grip and cable together. For instance, many cord grips slide over the cable and tighten onto the jacket. Some are permanently molded to the cable. Snap-on cord grips are also available.

Why Use Cord Grips?

An essential component of cable management, cord grips ensure that your cables stay neat and orderly for easier maintenance and service. But they also provide many other benefits that support constant uptime and reduce the likelihood of cable damage or disconnection.

Cord grips can:

- Act as a seal and protect against damage from dirt, dust, sand, debris, oil, or moisture

- Prevent cables from being pulled out of equipment or twisted loose

- Protect cables from stress and damage as they run through equipment panels

- Relieve strain on the connection and equipment circuitry to prevent against wear

- Provide a safe connection point that guards against sparks or arc flash

- Supply earth grounding when a metal cord grip is used with an armored cable

- Offer an appropriate level of resistance for adequate tension or holding force

Where are Cord Grips Used?

Cord grips can connect all types of electrical power, control, instrumentation, data, and telecommunications cables to devices and power supplies. You’ll often find them used in aerospace applications, cleanroom environments, utilities, industrial settings (such as automotive or food and beverage manufacturing plants), and marine and railway applications.

In hazardous or harsh environments, cord grips may also be called upon to prevent flammable gas (or other potentially flammable substances) from entering equipment enclosures.

How Can You Select the Right Cable Gland?

To make sure you choose a cord grip that will work for your specific application, ask yourself these questions:

- What type of cable will the cord grip connect to? Consider cable diameter, type, voltage rating, etc.

- Where will the cable be located? Indoors or outdoors? In a potentially hazardous/explosive environment? Will temperatures fluctuate or stay the same?

- Are liquids present?

- Will consequences be severe if these cables become disconnected?

Your answers will help determine the size and type of cord grip you choose – as well as the type of gland mounting you need: adhesive, threaded or nut mount, welded, etc.

3 Considerations You Should Think About When Selecting Cord Grips

Standout Features: Cord Grips that Go Above and Beyond

Some cord grips offer additional features that can lead to even better reliability, faster assembly, and ease of use. They can help you:

- Reduce inventory and SKU numbers, saving time, space, and money. Look for cord grips with wide clamping ranges that accommodate a wider range of cable diameters.

- Complete installation faster. Multi-trapezoidal threads can tighten and automatically adjust to the size of your cable with just one twist while providing excellent strain relief and assurance that cables are perfectly centered, secured, and hermetically sealed. This also makes them easier to install in hard-to-access places, such as dual-wall enclosures or temperature-controlled assemblies that include insulation.

- Ensure proper installation. Invest in a cord grip with an aural indicator (such as a “click”) that lets you know when the cap is locked correctly into place.

- Prevent seating and fit issues by selecting a cord grip with lamellar fins that end at the surface of the cord grip’s body instead of extending beyond it.

- Achieve better performance in high-vibration environments, with ratcheting ridges located inside the dome cap that ensure proper lock engagement and prevent the cap from coming loose despite vibration from air-handling systems, unbalanced fans, pumps, etc.

- Maintain cable performance despite temperature extremes and fluctuations. Select a cord grip that performs well in cold and hot temperatures, as well as resists degradation from UV rays and sunlight.

- More easily grip, handle, and mount the cable gland. Look for a cord grip with an ergonomically designed cap.

Want to learn more about cord grips and how they can guard against downtime and equipment failure? Chat with one of our agents for more assistance.

Everything You Need to Know About Cord Grips

Heavy-duty cables are found everywhere you turn – from arenas and large facilities to commercial buildings. They play a vital component in bringing our indoor environments to life.

Now imagine what could happen if one of these cables disconnects. Unplanned outages, equipment malfunction, and downtime could lead to potential injury, missed production deadlines, and efficiency interruptions – all negatively impacting the bottom line.

Cord grips are crucial in ensuring uptime and preventing cable disconnects. However, they aren’t always given adequate consideration when planning cable infrastructure. For a small investment, cord grips guard against downtime and equipment failure.

What is a Cord Grip?

Cord grips are devices that attach and secure heavy-duty cables to equipment. They can seal around single or multiple wires or cables – armored or unarmored.

Cord Grips vs. Cable Glands

Cord grips and cable glands are different names for the same thing, with cord grip being more commonly used within the United States. Depending on the region you are located in, they may be known as cable glands, connectors, strain relief, or fittings. Here at LAPP Tannehill, we tend to use 'cord grip' and 'cable gland' interchangeably.

What are Cord Grips Made Of?

Most cord grips are made up of three components: two “halves” and a grommet.

- The front half of the cable gland secures the gland itself, often called a cap nut or dome cap.

- The middle section (grommet) seals and locks the cable into place so it can’t be pulled or tugged loose.

- The final half holds the entire gland together, often called the thread.

To withstand a variety of environments, cord grips are available in a variety of metals and plastics. The right choice depends on your application. Some of the most common materials include:

Metal

- Aluminum is lighter in weight than stainless steel, offers excellent electrical and thermal conductivity, and resists corrosion and wear

- Brass offers high-temperature ductility, impressive bearing properties, high conductivity, good corrosion resistance, and low magnetic permeability

- Stainless steel provides chemical and corrosion resistance, better tensile strength than aluminum, and durability even in wet conditions

Plastic

- Nylon is durable and lightweight, withstands moisture and corrosion, and is available in different colors for cable color coding (which can support easier maintenance)

- PVC is flexible and easy to clean and is also ideal in food and chemical processing environments because it resists salt water, grease, and weak acids

There are also different choices you can make when it comes to joining a cord grip and cable together. For instance, many cord grips slide over the cable and tighten onto the jacket. Some are permanently molded to the cable. Snap-on cord grips are also available.

Why Use Cord Grips?

An essential component of cable management, cord grips ensure that your cables stay neat and orderly for easier maintenance and service. But they also provide many other benefits that support constant uptime and reduce the likelihood of cable damage or disconnection.

Cord Grips Can:

- Act as a seal and protect against damage from dirt, dust, sand, debris, oil, or moisture

- Prevent cables from being pulled out of equipment or twisted loose

- Protect cables from stress and damage as they run through equipment panels

- Relieve strain on the connection and equipment circuitry to prevent against wear

- Provide a safe connection point that guards against sparks or arc flash

- Supply earth grounding when a metal cord grip is used with an armored cable

- Offer an appropriate level of resistance for adequate tension or holding force

Where are Cord Grips Used?

Cord grips can connect all types of electrical power, control, instrumentation, data, and telecommunications cables to devices and power supplies. You’ll often find them used in aerospace applications, cleanroom environments, utilities, industrial settings (such as automotive or food and beverage manufacturing plants), and marine and railway applications.

In hazardous or harsh environments, cord grips may also be called upon to prevent flammable gas (or other potentially flammable substances) from entering equipment enclosures.

How Can You Select the Right Cable Gland?

To make sure you choose a cord grip that will work for your specific application, ask yourself these questions:

- What type of cable will the cord grip connect to? Consider cable diameter, type, voltage rating, etc.

- Where will the cable be located? Indoors or outdoors? In a potentially hazardous/explosive environment? Will temperatures fluctuate or stay the same?

- Are liquids present?

- Will consequences be severe if these cables become disconnected?

Your answers will help determine the size and type of cord grip you choose – as well as the type of gland mounting you need: adhesive, threaded or nut mount, welded, etc.

3 Considerations You Should Think About When Selecting Cord Grips

Standout Features: Cord Grips that Go Above and Beyond

Some cord grips offer additional features that can lead to even better reliability, faster assembly, and ease of use. They can help you:

- Reduce inventory and SKU numbers, saving time, space, and money. Look for cord grips with wide clamping ranges that accommodate a wider range of cable diameters.

- Complete installation faster. Multi-trapezoidal threads can tighten and automatically adjust to the size of your cable with just one twist while providing excellent strain relief and assurance that cables are perfectly centered, secured, and hermetically sealed. This also makes them easier to install in hard-to-access places, such as dual-wall enclosures or temperature-controlled assemblies that include insulation.

- Ensure proper installation. Invest in a cord grip with an aural indicator (such as a “click”) that lets you know when the cap is locked correctly into place.

- Prevent seating and fit issues by selecting a cord grip with lamellar fins that end at the surface of the cord grip’s body instead of extending beyond it.

- Achieve better performance in high-vibration environments, with ratcheting ridges located inside the dome cap that ensure proper lock engagement and prevent the cap from coming loose despite vibration from air-handling systems, unbalanced fans, pumps, etc.

- Maintain cable performance despite temperature extremes and fluctuations. Select a cord grip that performs well in cold and hot temperatures, as well as resists degradation from UV rays and sunlight.

- More easily grip, handle, and mount the cable gland. Look for a cord grip with an ergonomically designed cap.

Want to learn more about cord grips and how they can guard against downtime and equipment failure? Chat with one of our agents for more assistance.