No Chance for Interference Currents: LAPP as an EMC Technology Partner

-

LAPP Tannehill

LAPP Tannehill - Product News

- May 28, 2024

- 887views

No Chance for Interference Currents: LAPP as an EMC Technology Partner

Original Content Written By: LAPP

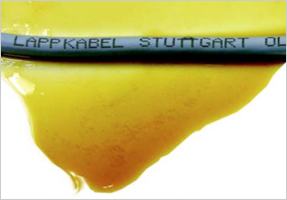

Avoid interference from electromagnetic fields in industrial applications with shielded cables, cable glands, and connectors from LAPP.

In the smart factory, high electrical power and an increasing amount of data are transferred in a tight space. This increases the risk of electromagnetic interference – even one poorly screened connector can paralyse an entire production process. So it's no wonder that the industry for electromagnetically compatible solutions is on the rise – currently at seven percent per year worldwide. Optimum electromagnetic compatibility (EMC for short) requires a good understanding of the system and the selection of the right components. Users get both from LAPP.

Read the EMC whitepaper, where LAPP experts answer the most important questions on the topic of EMC: EMC Problems in Production and How to Avoid Them.

How does EMC work?

An electromagnetic interference always originates from an interference source. This can be an item of equipment that carries a high current, such as a frequency controlled motor or a cable.

The source of interference corresponds to a disrupted piece of equipment, known as the interference sink. The interference sink can be a sensor or data network cable, for example.

The coupling mechanism in between causes the interference. This can be divided into four different types of coupling:

- Conductive coupling: The interference source and interference sink are linked with one another, for example by means of a common earthing conductor. An interference current via the common earthing conductor causes electromagnetic interference.

- Capacitive coupling: The interference source and interference sink are close to one another, but not physically connected. With capacitive coupling, the electromagnetic interference (EMI) is produced by the electric field.

- Inductive coupling: With inductive coupling, the interference source and interference sink are also close to each other, but are not connected to one another. However, the interference is caused by the magnetic field.

- Radiative coupling: Radiation coupling generally occurs when the interference source and interference sink are far apart and the conductors ultimately act as antennae and cause the interference from electromagnetic radiation.

In practice, this is usually a mixture of these 4 coupling mechanisms, which must be eliminated, for example by using screened cables.

EMC check with the LAPP Health Check Service

What is the EMC directive?

In EMC Directive 2014/30/EU, Article 3, electromagnetic compatibility is defined as:

"[...] the ability of a piece of equipment to operate satisfactorily in its electromagnetic environment without causing electromagnetic interference, which would be unacceptable for other equipment in this environment."

According to this definition, EMC has two main aspects:

- The equipment must not cause electromagnetic interference.

- The equipment must not be electromagnetically disrupted by its surroundings.

How to Ensure Good EMC

Power and Control Cables

Energy-carrying cables can have different types of screening:

- Tin-plated copper braiding between the cores and the sheath. The degree of coverage and the angle of braiding influence the effectiveness of the barrier.

- Example: ÖLFLEX® SERVO 719 CY

- Copper wire wrapping. Especially for moving cables in robotics that need to withstand torsion.

- Example: ÖLFLEX® ROBOT 900 DP

- Aluminum-laminated plastic foil, which is wrapped around individual or all cores. Often in combination with braided screening.

Data Cables

These are usually screened. It is common to strand as a twisted pair, which removes field effects in the core pairs. In addition, these cables have foil screening over the cores and a braided screen on top of that. LAPP experts will advise you on the selection process.

Connectors

EPIC® EMC connectors feature 360-degree screening and vibration-proof screening connection. Cable glands from the SKINTOP® BRUSH series ensure easy assembly and maximum EMC.

Cable Glands

LAPP connector systems have the advantage of using all the aforementioned screening connection concepts. Very often, EMC cable glands are already integrated into the connector, offer the option of connecting a protective conduit and enable the cable screening to be contacted with the working or PE contact of the connector system. Rectangular connectors have an integrated SKINTOP® MS-M BRUSH cable gland. The EPIC® ULTRA H-A3 and the EPIC® ULTRA H-B6-24 are therefore easy to assemble and designed for a wide cable clamping range in screened cables. If you need a space-saving design, for example for use in servo drives, actuators and sensors, we recommend the POWER and SIGNAL circular connectors from LAPP. These are equipped with a specially coordinated EMC cable gland for servo and data cables.

Accessories, Conductor strands & earthing blocks, System

It is important to have high-quality components for industrial communication from a single source, such as patch cables and switches. LAPP offers a health check service that tests cabling in a factory or individual systems, paying particular attention to EMC.

Earthing

Good earthing is fundamental for EMC, otherwise the screening will have no effect. Data cables should always be connected to the earthing at both ends.

Installation

During assembly, it is important to ensure that the shielding always covers the entire surface and is placed all around in a housing – at both ends of the cable. The Fast Connect system prevents errors during assembly and saves time. It's even easier with ÖLFLEX® CONNECT: here, all cables are pre-assembled and have the right length, all you need to do is plug them in.

How are screened power and control cables constructed?

There are four different screening types for power and control cables. Three of these shields are particularly suited to use with EMC protection:

Tin-plated copper braiding

A common method of screening cables is braided copper between the cores and the sheaths. With a degree of coverage of around 80 percent, the copper braiding forms an effective barrier against electromagnetic fields. These cables can be identified by the abbreviation "C" in the LAPP product designation, e.g. ÖLFLEX® CLASSIC 110 CY or ÖLFLEX® SERVO 719 CY . Copper braiding can be done in different ways, with one of the crucial parameters being the angle of twist. In highly dynamic applications, such as the installation of the cable in a drag chain, the copper wire is routed around the cores at a more obtuse angle, so that it creates a full 360-degree wind around the cores over a shorter distance. In robot cables that need to withstand millions of torsions, braiding is not ideal because gaps occur over time.

Copper wire wrapping

For moving cables in robotics, where the screening must withstand torsion, copper wire wrapping is often used. As the copper wires in a wrapping are all positioned parallel to each other, there is no problem with the cable torsion. However, the protection against electromagnetic interference from wrapped cables is often worse as the shield wires do not overlap. These cables can be identified by the abbreviation “D” in the LAPP product designation, e.g. ÖLFLEX® ROBOT 900 DP.

Aluminum-laminated plastic foil

Individual cores or all cores in the cable can be wrapped with laminated aluminum plastic foil. The plastic foil screening protects your cables and wires, especially at higher frequencies. Cables often also have several screening types, e.g. the ÖLFLEX® SERVO 2XSLCY-JB with aluminum-laminated plastic foil and tin-plated copper braiding.

How are screened data cables constructed?

Data cables have essentially the same screening as power and control cables, but other abbreviations are common in product designations:

- Tin-plated copper braiding: „S“ (Screened)

- Aluminum-laminated plastic foil: „F“ (Foiled)

There are also two special features for data cables in terms of their screening rating for EMC protection:

Unscreened

Data transmissions are particularly susceptible to interference, which is why data cables are generally always screened. For certain areas of application for signal transmission, there are unscreened data cables specially marked with the abbreviation “U” (unscreened), such as the Cat.6 network cable ETHERLINE® LAN Cat.6 U/UTP 4x2xAWG24 LSZH, the Cat.5e Ethernet cable ETHERLINE® LAN Cat.5e SF/UTP 4x2xAWG24 or our UNITRONIC® BUS ASI cables for networking systems in the field.

Twisted Pair

Another design for data cables is twisted pair cables. Individual data pairs are twisted here. The twisting ensures that field effects compensate each other. These cables can be identified by the abbreviation “TP” (Twisted Pair). For instance, the ETHERLINE® Cat. 6A FD FC cable is divided up as follows:

ScreenedFoiled/UnscreenedTwistedPair. This network cable is screened around all cores with a wire braid and an aluminum-laminated plastic foil underneath (screened/foiled). The core pairs are twisted in pairs and are not equipped with additional core pair screening (UnscreenedTwistedPair).

Why are connectors important for EMC protection?

Every system is only as good as its weakest point. LAPP connector systems have the advantage of using all the aforementioned screening connection concepts. Very often, EMC cable glands are already integrated into the connector, offer the option of connecting a protective hose and enable the cable screening to be contacted with the working or PE contact of the connector system.

The standard housing is powder-coated with a non-conductive seal between the housing parts, which insulates them from one another. EPIC® EMC connectors offer 360-degree screening and vibration-proof screening connection. The EMC connectors can be identified by their metallically conductive, usually nickel-plated surface. The seals are designed to ensure that the two housing parts pressed or screwed together are in low-resistance contact with metal on metal. The same principle applies to both cable glands and the mounting wall.

Rectangular connectors feature an integrated SKINTOP® MS-M BRUSH cable gland. EPIC® ULTRA H-A3 and EPIC® ULTRA H-B6-24 are therefore easy to assemble and designed for a wide cable clamping range in screened cables.

If you need a space-saving design, for example for use in servo drives, actuators and sensors, we recommend the POWER and SIGNAL circular connectors from LAPP. These are equipped with a specially coordinated EMC cable gland for servo and data cables.

Milestone for EMC: zeroCM® technology from LAPP

The zeroCM® technology from LAPP makes a key contribution to improved EMC in machines and systems. The new and patented cable design with a low-capacitance bundle construction with an opposite protective earth achieves one hundred percent electrical symmetry and improves electromagnetic compatibility. The first product is the ÖLFLEX® SERVO zeroCM.

Always EMC protected with the service from LAPP

Electromagnetic interference cannot be seen, which is what makes it so insidious. It takes a lot of experience to detect it, ideally before it causes damage. LAPP has a comprehensive range of products to support its customers:

- 60 years of research and development on the topic of EMC

- A wealth of specialist experts with EMC expertise

- A portfolio of EMC-optimised cabling and connection solutions

- zeroCM®: a milestone for EMC-optimised cables

- Always in compliance with all current guidelines and standards, in all industries worldwide

- The Health Check Service identifies and eliminates sources of electromagnetic interference

How you benefit as a customer:

- Prevent faults and failures

- Get maximum efficiency and quality in production

- Avoid time-consuming reworking, troubleshooting and repair costs

- You do not have to worry about adapting to new regulations and standards

How can unscreened cables and cables be screened afterwards?

If an unscreened cable is not possible in the system for various reasons, or if cables only need to be electromagnetically screened in certain sections of the system, the LAPP protective conduits can also be equipped with our SILVYN ® conduits as well with copper braids or wrapped in the 3M Scotch 1183 screening tape.

For these systems, LAPP offers a one- and two-part screening connection for connecting the copper braiding to a housing wall or a connection contact for looping through the cable shield.

How can EMC protection be improved?

To ensure optimum screening, cables can be fitted with double screening or installed in a copper or steel pipe. From an EMC perspective, these screens are completely sealed. LAPP SILVYN® offers you the optimum EMC protection. The EMC AS-CU protective conduit from the SILVYN® product brand is a metal protective conduit with copper braiding and is therefore suitable for particularly harsh environments with high electromagnetic requirements. The SILVYN® MSK-M BRUSH conduit gland with EMC protection and integrated strain relief rounds out your EMC-screened system.

Are there pre-assembled power, control, and data cables with EMC screening?

Poor EMC is often the cause of installation errors. For a long time, it was customary in industry to buy cables and plugs separately and only connect them when installing them in a machine or production plant, for example.

There are a few disadvantages to greater flexibility: processing quality often leaves a lot to be desired. For instance, if the installer cuts too deep when stripping and damages the core insulation or only partially connects the screening to the housing of the plug, causing EMC problems.

This is why the trend is towards ready-assembled cables, which we at LAPP sell under the name ÖLFLEX® CONNECT. The cable and plug are already connected ex works. Customers even receive drag chains fully equipped with cables and hoses, and LAPP also takes over the engineering work. Customers are therefore guaranteed to always receive optimal quality from a single source and can also concentrate on their own work, namely building machinery.