What are the Different Types of Flexible Cables?

When looking to spec in a cable that will work for your application, the cable’s degree of flexibility is an important and often overlooked, factor to consider. Some cables are physically flexible, which can ease routing concerns during installation, but other cables are actually designed to be installed in flexing applications with different types of motion.

Without considering the type of flexibility you need from your cable, you could choose the wrong cable and that will then have a reduced life cycle. Making the right choice the first time will save you the headache of your system going down and trying to identify the right cable in a hurry. If you have any questions about flexible cable, please contact us at the button below to get in touch with one of our wire and cable professionals.

So, what physical properties make a cable more flexible?

The type of insulation material used, whether or not there is a shield, wrap, or fillers, and the conductor’s stranding are factors in this equation. With this, it is also important to note the number of flex cycles that the cable can withstand, the cable’s weight, the type of flexing motion that the cable is capable of performing, and the cable’s bend radius. While the cable’s bend radius tells you how tightly the cable can bend without damage, it does not tell you that the cable can be used without damage in a motion application where there is constant movement at that bent angle.

Types of Cable Flexibility

There is no official, acknowledged scale or terminology to define different types of cable flexibility, but below we detail the most standard cable flex types and the applications where each is the best option.

Stationary

Bending Flex

Continuous Flex

Torsional Flex

NON-MOTION RATED

Stationary

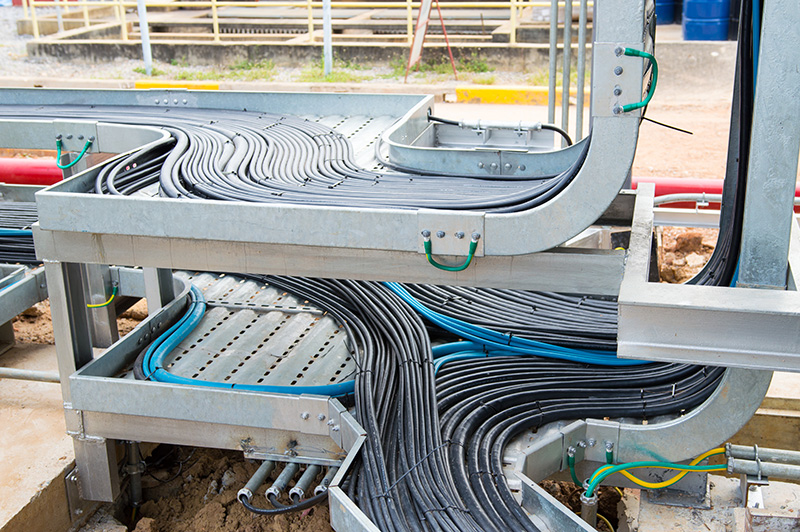

Cables rated for stationary motion will be mostly rigid with some give, but these are meant to be installed in static applications. These are rated for no movement and are commonly used in stationary trays, audio and studio broadcast systems, instrumentation systems, and more. Stationary cables are a very common and cost-effective solution, but you must be sure that the cable will not need to be routed around corners during installation, and that no bending or flexing of any kind will be required.

Stationary – For Routing

If the cable will lay static in your application, but needs to be routed through machinery or within cable trays with corners or curves, a degree of flexibility is required during initial installation. For applications like this, we recommend that you look into cables rated for flexible applications instead of stationary. Many times during installation the cable is too stiff to be properly routed and the installer cannot route the cable or has difficulty doing so. This can lead to high costs due to downtime and finding a cable replacement, so we will always recommend a more flexible solution that will not break the bank.

Common stationary cables with extra flexibility for routing and installation include LAPP ÖLFLEX®490P and LAPP ÖLFLEX® Classic 100.

MOTION RATED

Flexible

Most high-quality cables that you see on the market are rated for some amount of flexibility. In applications where a flexible cable would be appropriate, usually, one end of the cable is stationary and the other moves. In an application like this, the cables are not moved constantly. Typically, these cables are not tested to withstand any number of flex cycles, but some manufacturers claim to have tested their flexible cables up to 1 to 12 million flex cycles. Your best bet will be to check the manufacturer’s flex cycle testing information since manufacturers consider different factors when calling a cable flexible, continuous flex, or other. Typical uses for such cables include cable tray routing, portable power equipment, wind and solar energy, oil and gas applications, and more.

LAPP ÖLFLEX® VFD 2XL, LAPP ÖLFLEX® 409 P, ÖLFLEX® 190/190 CY, and ÖLFLEX® VFD SLIM are common flexible cables.

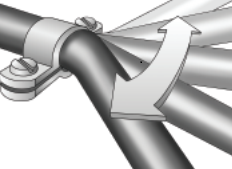

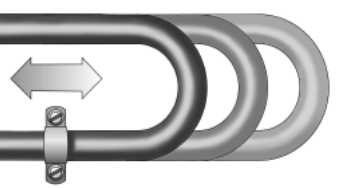

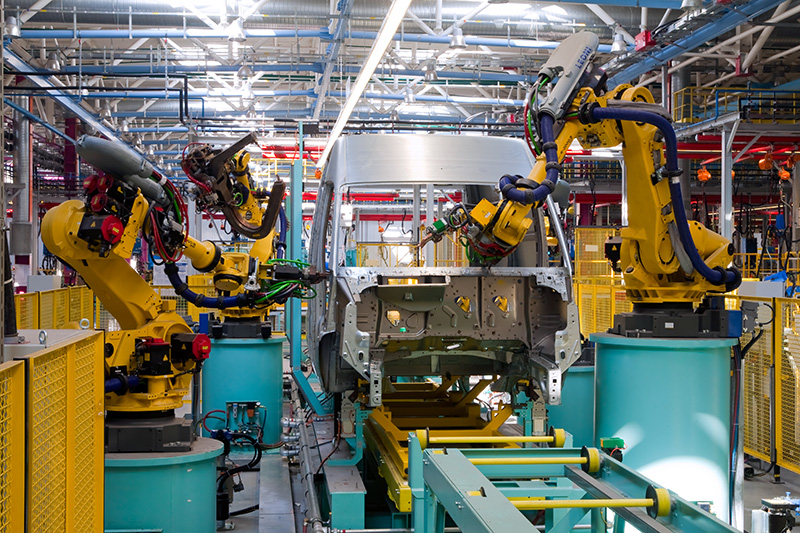

Continuous Flex (Rolling flex, Bending flex)

Cables that are used in continuous flex applications are tested for use between 1 and 20 million flex cycles. This large range means that, once again, you should check the manufacturer’s testing conditions to determine what they mean by the cables being rated for “continuous flex” applications such as moving robotics, continuously moving gantries, etc. For example, LAPP has a very specific cable motion classification, where the cycle life range, description of movement type, and a motion “level” are assigned as an easy way to determine what type of cable would be best suited for your application. Applications for continuous flex cables range from rolling flex applications like in cable track installations to bending flex applications where the cable is continuously moving but in a more variable or random fashion, as these applications are usually not automated.

Common continuous flex cables are LAPP ÖLFLEX® CHAIN TM and CHAIN TM CY, LAPP ÖLFLEX® Servo 7DSL, ÖLFLEX® FD 855 P, ÖLFLEX® FD 855 CP, UNITRONIC® FD 890, and UNITRONIC® FD/FD CY.

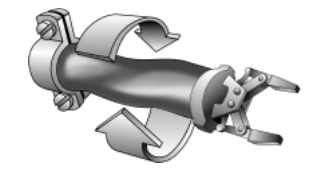

Torsional Flex

Cables rated for torsional flexing will be constantly twisting around an axis. This cable may be pulled back and forth, combined with bending and/or rolling motions. Typical applications include robotic pick and place, as well as applications where a cable will rotate 360 degrees around an axis. These applications oftentimes involve repetitive movement through a fixed range of motion for the duration of the cable’s life cycle. Like with all other types of cable rated for flexing motion, torsional cables are typically tested between 2 and 14 million cycles, depending on the manufacturer.

Common torsional flex cables include LAPP ÖLFLEX® ROBOT F1 and F1(C), LAPP ÖLFLEX® ROBOT 900 P and ROBOT 900 DP, and ETHERLINE® TORSION.

Conclusion

Though terminology and testing standards are not uniform across all manufacturers, knowing which type of motion stress your cable will be under is important in order to choose a cable with the correct level of bendability and flex life. It could save you a lot of time, money, and headache in the future.

For more detailed information on LAPP cable ratings and flex life, refer to the datasheet of the specific product you're interested in and reference the technical information section linked below.

LAPP Cable Motion Types & Levels

For questions about what type of flex cable you may need, feel free to reach out to a Lapp Tannehill customer service representative at 800.633.6339 or chat with us online.